Now a pioneer in the global barrel trade, River Drive started out in quite a different and unusual way.

In 2005 New England native and River Drive founder Matt Albrecht traveled to Maine for school. Studying for 4 years, Matt got two degrees from a small southern Maine college, one in Fire Science and one in Paramedicine. Matt had already been a third generation firefighter since age 14, and an EMT since 16.

With this advanced training and education, he was quickly hired in Maine as a career firefighter and paramedic… But there was always room for more.

In 2008, after a Caribbean vacation introduced him to SCUBA diving, Coastland Diving LLC was founded, providing basic underwater services in the local community. That, and continued research on the history of Maine, led Matt to discover hidden treasure within the remote waterways of Maine. You see, Maine has been known for its timber industry, but before the days of log trucks, lakes and rivers were used to move large amounts of timber to the mills. These were the days of the river drives, when the tough men and tall trees ruled the woods. As trees became waterlogged while floating down river, some sunk to the bottom. Here, they were shielded from sunlight, oxygen, and pests, preserved for over 100 years.

Matt lives with a “what’s next” point of view. He learned how to save lives, so, what’s next? Save our resources. Coastland Diving LLC was now doing business as River Drive Lumber, a reclaimed lumber company. As you can imagine, the waterways of Maine aren’t always the warmest. Actually, they’re never really warm. So, with inspiration from a colleague, he took an old pontoon boat, fitted it with sonar, underwater cameras, and a log grapple, and started salvaging these long forgotten logs without even having to get in the water.

Matt lives with a “what’s next” point of view. He learned how to save lives, so, what’s next? Save our resources. Coastland Diving LLC was now doing business as River Drive Lumber, a reclaimed lumber company. As you can imagine, the waterways of Maine aren’t always the warmest. Actually, they’re never really warm. So, with inspiration from a colleague, he took an old pontoon boat, fitted it with sonar, underwater cameras, and a log grapple, and started salvaging these long forgotten logs without even having to get in the water.

So, what’s next?

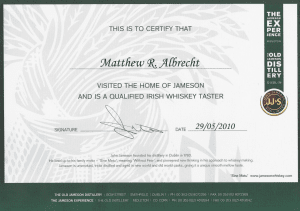

After a trip to Ireland, Matt returned a self proclaimed Professional Whiskey Taster. At least that’s what the free certificate said that he got after his tour at the Old Jameson Distillery in Dublin, Ireland. But let us not rest on our laurels. Matt did gain an appreciation for spirits and the wooden barrels they were aged in. That’s when it dawned on him; the typical wooden wine and whiskey barrels we all know and love haven’t really changed much since their inception. The design is just that perfect. Name one other item that has remained unchanged for hundreds, if not thousands of years. (Feel free to do so in the comments!)

So Matt saw that in two ways. First as inspiration.

Matt started salvaging old, used barrels from breweries and added Whiskey Wood™ to his reclaimed wood catalogue. That’s when the business really started to grow. Pinterest was just starting to become popular and the reclaimed barrel wood demand was starting to grow, but not many people understood the technical aspects of using barrel wood for projects. For one, the wood is very wet from the beer, wine, and spirits they held for so long, and needs to be properly dried before the staves are stable for use in crafts and projects. Second, it used to hold beverages, which are organic material, and also needs to be properly sanitized to prevent mold or bacterial growth.

This is what Matt saw second, a challenge.

How do we revolutionize, change, and possibly improve something that was designed so long ago? Matt engineered myriad processes to help with this, from specific drying schedules to [re-]infusion technology. Many of these ideas not only enhanced the lifespan of the barrels, but also improved their end-of-life use. Matt wasn’t just interested in selling barrels and barrel wood. He carefully tracked and monitored their every use. He wanted to know three things; Why are people interested in barrels? What problems do they run into? How can I help fix those problems? He started talking to the breweries who were using these barrels, some with great struggle, and researched the philosophies they were following and the problems they were having.

- Full size barrel

In 2012, River Drive Lumber became River Drive, a cooperage and millwork company that was no longer salvaging timber, but now focusing on barrels. Matt began traveling the country sourcing the best barrels he could find for breweries and distilleries to use, repairing and reconditioning those that were not in the best shape, and recycling those that were no longer useable for aging. So, what’s next? River Drive continues to research and develop new technology, techniques, and processes that improve the barrel aging experiences for all users. Now working off a global platform, Matt travels the world hand selecting casks and barrels to bring to his clients.

In addition, he personally teaches breweries and brewers how to get the most out of their barrel programs through educational seminars, classes, and hands on workshops. River Drive has created a foundation for success that’s based off of three things that were previously hard to achieve in the barrel industry; Quality, consistency, and control.